How to control quality of split air...

How to control quality of split air conditioner service valve?

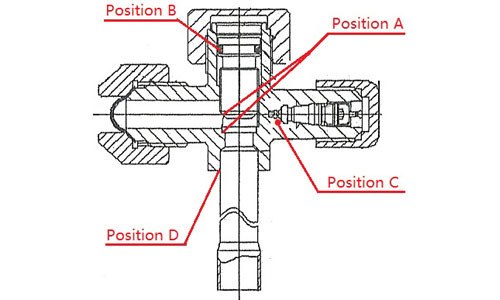

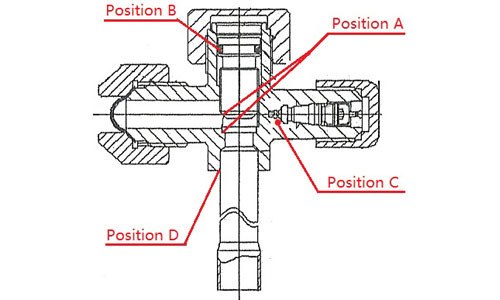

As a professional manufacturer of split air conditioner service valve, it is a key to avoid leaking in Position A, B, C and D. How to control quality inspection during the course of produciton line?

Here is our inspecting steps of a/c service valve below.

First, let us test Position A, B and C. Before making this test, valve stem with O ring and valve core have been finished into a/c valve. At the same time we also need necessary testing equipment machine like water trough with switch and Nitrogen gas with regular, which control gas pressure to locate 3.0MPa.

We make air conditioner service valve with water trough, and then completely turning off valve stem. At last we open the switch on water trough, N2 gas will be filled in a/c valve. If we find out blisters nearby valve, it proves this valve leaking. Otherwise, it is a good qualtiy valve.

Regarding test of Position D, we should try to make more brazing material in a/c valve hole. If you only braze this connection between brass and tube, it looks more brazing material in tube surface, but there is no any brazing in hole. The connection is still poor. In a word, Position A test is the most important compared other positions, which needs a high quality valve stem to perfectly suit for valve boday, especially stem bottom toughing valve boday. It is a key to recognize a good or bad air conditioner service valve.

Hope above suggestions are helpful to you. In case that your a/c valve leaks in working, it is welcome to let us know and we'll help you to analysis the leaking reason, how to improve this quality problem.

Here is our inspecting steps of a/c service valve below.

First, let us test Position A, B and C. Before making this test, valve stem with O ring and valve core have been finished into a/c valve. At the same time we also need necessary testing equipment machine like water trough with switch and Nitrogen gas with regular, which control gas pressure to locate 3.0MPa.

We make air conditioner service valve with water trough, and then completely turning off valve stem. At last we open the switch on water trough, N2 gas will be filled in a/c valve. If we find out blisters nearby valve, it proves this valve leaking. Otherwise, it is a good qualtiy valve.

Regarding test of Position D, we should try to make more brazing material in a/c valve hole. If you only braze this connection between brass and tube, it looks more brazing material in tube surface, but there is no any brazing in hole. The connection is still poor. In a word, Position A test is the most important compared other positions, which needs a high quality valve stem to perfectly suit for valve boday, especially stem bottom toughing valve boday. It is a key to recognize a good or bad air conditioner service valve.

Hope above suggestions are helpful to you. In case that your a/c valve leaks in working, it is welcome to let us know and we'll help you to analysis the leaking reason, how to improve this quality problem.

Previous:

Brass Flare Fittings - Forged

Next:

Air Conditioning System Diagno